Combined Heat and Power Helps Groceries Reduce Costs and Increase Resiliency

OVERVIEW

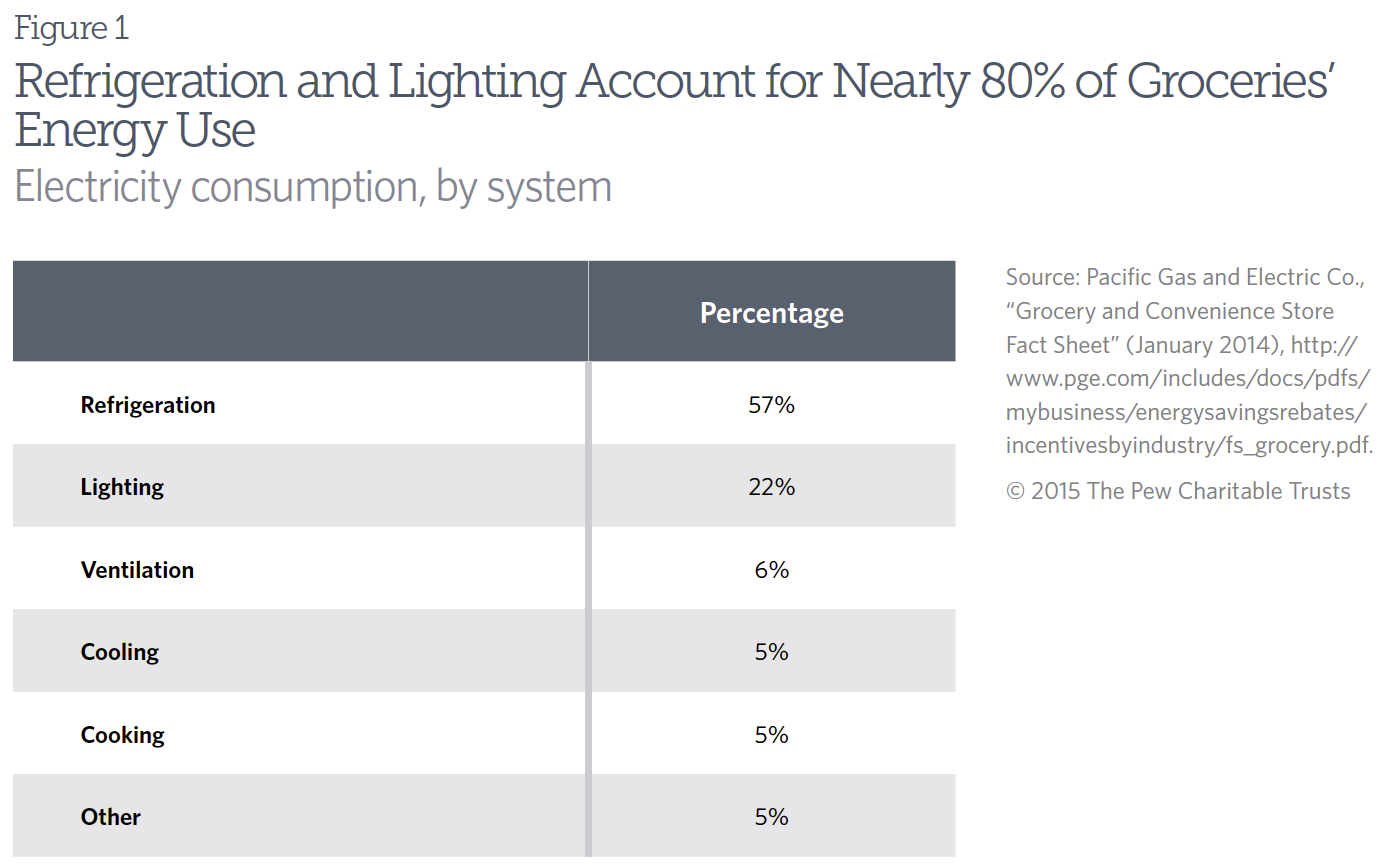

Commercial operations consume about 20 percent of the total energy used in the United States each year.1 Within this sector, grocery stores are among the most power-intensive businesses. According to the U.S. Census Bureau, 93,200 groceries operate nationwide and, as a group, spend more than $6 billion annually on electricity and natural gas, with refrigeration and lighting accounting for almost 80 percent of the energy consumption.2 Investment in efficiency, particularly combined heat and power (CHP)—a distributed generation resource that captures wasted heat to produce electricity and thermal energy through a single system—has tremendous potential to reduce costs and increase reliability for these facilities.

CHP systems offer cost reduction

Combined heat and power is ideal for food retailers and their warehouses, where round-the-clock operations require constant refrigeration to maintain the appropriate environment and temperature for perishable products. Because power costs can constitute as much as 15 percent of an operating budget, adopting efficiency technologies can translate into significant profit growth, according to Xcel Energy, a major U.S. electric and natural gas company.3

Facilities equipped with CHP technology have a proven record of reducing consumption. For example, a ShopRite supermarket in Brooklyn, New York, that constructed a 140-kilowatt system in 2005 to provide energy for refrigeration and heating, ventilating, and air conditioning has seen annual savings of $50,000.4

CHP systems also ensure a reliable energy source during power outages, which is critical to food suppliers’ business model. As a result of a five-day blackout in the Washington metro area, for example, one local business in 2012 lost all its refrigerated items—milk, dairy, meat, eggs—and frozen goods, at a cost of more than $100,000, because it had no backup power installed.5

Since Superstorm Sandy in 2012, supermarkets have increasingly been viewed as critical infrastructure along with gas stations; residents depend on food stores for provisions during major storms or other disasters. Northeastern states, including New York, Connecticut, and New Jersey, now recognize and encourage the use of CHP in groceries as a key strategy for building community resiliency.6 In 2012, Connecticut began offering food retailers financial incentives to help businesses design and install CHP systems that will recoup the initial costs in a reasonable time frame and deliver an acceptable return on investment while ensuring that facilities can function during blackouts.7

We have designed one of America’s most sustainably built retail establishments. The new store is approximately 60 percent more energy efficient than your average grocery store.”Tristam Coffin, LEED AP, green mission team at Whole Foods Market

© Getty Images

© Getty ImagesCHP could supply 1.2 additional gigawatts at supermarkets

A study commissioned by the U.S. Department of Energy found almost 1.2 GW of unrealized CHP capacity at supermarkets nationwide, which could provide hundreds of stores with a proven, reliable way to reduce costs and improve operational efficiency. California, Texas, Florida, and New York are expected to have the most new installations, representing 374 megawatts, or almost a third of all added capacity.8 Across the country, 30 locations already employ the technology and reap these benefits:

- Price Chopper, headquartered in Schenectady, New York, has adopted CHP to help meet its green energy initiatives and respond to high electrical prices in the Northeast. At its Glenville, New York, store, a unit provides hot water, space heating, refrigeration, and lighting. Constructed in 2011, the 200-KW system is 90 percent efficient and expected to yield 30 percent annual savings on utility bills while delivering standby power in the event of a grid failure.9

- Food Lion, a leading regional supermarket chain with more than 1,200 stores in the Southeast and Mid-Atlantic, has installed units at six North Carolina stores. These projects produce almost 2.4 MW of electricity and helped the company achieve Energy Star recognition from the Environmental Protection Agency for reduced consumption.10 Since 2000, Food Lion has become 25 percent more efficient, due in large part to the adoption of CHP.11

- Whole Foods Market recently installed a CHP system at its Brooklyn, New York, location.12 The 157-KW unit provides heating and chilled water year-round and is designed to keep the power on in the event of a blackout.13 As Tristam Coffin of the LEED AP, green mission team at Whole Foods Market observed, “We have designed one of America’s most sustainably built retail establishments. The new store is approximately 60 percent more energy efficient than your average grocery store.”14

Federal tax policy needs updating to increase deployment

Installation of CHP systems requires upfront funding that typically is recovered through operational savings over the life of the equipment. To garner the full benefits of this technology, businesses need initial financing to cover equipment, construction, and regulatory or permitting fees. The federal investment tax credit, which provides an incentive for industrial energy efficiency projects, is a good start, but more is needed to encourage development, create parity among clean and efficient technologies, and shorten the time it takes to recoup project costs.

In particular, the tax credit requirements are restrictive, limiting the size of projects that qualify and rendering some innovative technologies that accomplish similar goals, including waste heat to power, ineligible. With small modifications, such as removing size restrictions and setting flexible incentives, the tax credit could enable more grocery stores or other major electricity consumers to embrace CHP and become increasingly resilient and productive.

Endnotes

1. U.S. Energy Information Administration, “Table 2.1 Energy Consumption by Sector,” Monthly Energy Review (November 2014), http://www. eia.gov/totalenergy/data/monthly/pdf/sec2_3.pdf.

2. U.S. Census Bureau, “Statistics of U.S. Businesses (SUSB) Main,” http://www.census.gov/econ/susb/index.html; and Applied Population

Laboratory, “North Central Region County Food Systems Profiles Portal: Data Definitions and Sources,” University of Wisconsin-Madison,

http://foodsystems.wisc.edu/links.php.

3. Xcel Energy, “Energy Savings Solutions for the Supermarket and Grocery Store Industry” (2011), https://www.xcelenergy.com/staticfiles/xe/Marketing/Files/Project-Grocery-Stores.pdf.

4. CDH Energy Corp., “ShopRite Supermarket CHP Aid Refrigeration and HVAC,” New York State Energy Research and Development

Authority, http://dataint.cdhenergy.com/Fact%20Sheets/Fact%20Sheet%20-%20ShopRite%20Supermarket%20-%20CHP.pdf; and

Groom Energy, “EC Motor Case Study,” http://groomenergy.com/emc-motor-case-study/.

5. Abha Bhattarai, “Business Assess Effects of Storm, Power Outage,” The Washington Post, July 11, 2012, http://www.washingtonpost.com/business/capitalbusiness/businesses-assess-effects-of-storm-power-outage/2012/07/11/gJQAla79dW_story.html.

6. Todd Olinsky-Paul, “Using State RPSs to Promote Resilient Power at Critical Infrastructure Facilities,” Clean Energy States Alliance (2013),

http://www.cesa.org/assets/2013-Files/RPS/Using-State-RPSs-to-Promote-Resilient-Power-May-2013.pdf.

7. Energize Connecticut, “Combined Heat & Power Pilot Program” (2015), http://www.energizect.com/businesses/programs/Combined-Heat-Power.

8. Onsite Sycom Energy Corp., “The Market and Technical Potential for Combined Heat and Power in the Commercial/Institutional Sector,”

U.S. Department of Energy, Energy Information Administration (January 2000), http://energy.gov/sites/prod/files/2013/11/f4/chp_comm_market_potential.pdf.

9. CDH Energy Corp., “Price Chopper, Glenville Fuel Cell Provides Cooling and Hot Water,” New York State Energy Research and

Development Authority, http://dataint.cdhenergy.com/Fact%20Sheets/Fact%20Sheet%20-%20Price%20Chopper%20Glenville%20-%20CHP.pdf.

10. ICF International, “Combined Heat and Power Units Located in North Carolina,” http://www.eea-inc.com/chpdata/States/NC.html; and

Energy Star, “Food Lion and Bottom Dollar Food: Energy Star Partner of the Year—Sustained Excellence,” https://www.energystar.gov/index.cfm?fuseaction=pt_awards.showAwardDetails&esa_id=5587.

11. Karen Kroll, “Energy Star, Portfolio Manager Can Help Make Capital Investment Decisions,” FacilitiesNet (September 2012), http://www.facilitiesnet.com/energyefficiency/article/Energy-Star-Portfolio-Manager-Can-Help-Make-Capital-Investment-Decisions-Facilities-Management-Energy-Efficiency-Feature--13465#.

12. Whole Foods Market, “NYSERDA Announced Whole Foods Market Flagship Store in Brooklyn Uses Energy Efficiency and Renewable

Energy to Reduce Costs,” http://media.wholefoodsmarket.com/news/nyserda-announces-whole-foods-market-flagship-store-inbrooklyn-uses-energy.

13. Ibid.

14. NYSERDA, “Whole Foods Market,” http://www.nyserda.ny.gov/About/Publications/Case-Studies/NCP-Case-Studies/Whole-Foods-Market.aspx.