Drug Shortages

An exploration of the relationship between U.S. market forces and sterile injectable pharmaceutical products: Interviews with 10 pharmaceutical companies

Overview

National drug shortages, defined by the U.S. Food and Drug Administration (FDA) as a period of time when the demand or projected demand for a drug within the United States exceeds the supply of the drug, remain a complex and multilayered issue in the U.S. health care delivery system. For the period 2011–14, FDA announced that there were 456 instances of drugs in shortage, a circumstance that can cause adverse outcomes for patients, including substitutions (alternate drugs) or modifications to treatment. In addition, the U.S. Government Accountability Office (GAO) reports that 6 out of 10 health care associations say the situation is static or worsening.

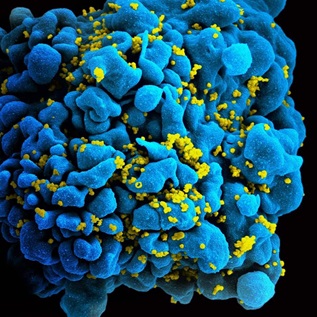

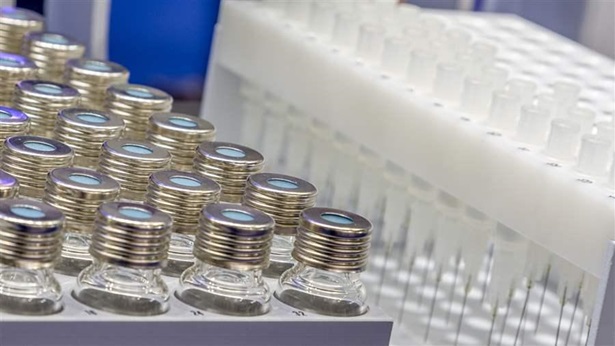

Drug shortages result in nearly $230 million in additional costs annually for hospitals because of the higher costs of substitute drugs. The majority of the shortages—more than 72 percent—were in the sterile injectable category, and the affected product categories or therapeutic classes ranged from anti-infective and anesthetic drugs to cardiovascular and oncology treatments.

The importance of preventing drug shortages, and the need to identify solutions, is evident from a July 2016 GAO report, which determined that multiple factors—including quality, manufacturing complexity, speed of regulatory reviews, decreased margins of certain drugs, and inventory-related issues—were associated with creating shortages.

A number of papers have examined drug shortages with a key focus on the quality-related root causes behind supply interruptions. For example, the International Society for Pharmaceutical Engineering (ISPE) conducted a survey of its membership and found that compliance, together with manufacturing and product quality issues, represented the single most important factor leading to drug shortages. And although other papers have explored the root causes of shortages outside of quality, this report explores the market dimensions and investments influencing supply chain and business continuity decisions, and their relationships to drug shortages.

The Pew Charitable Trusts and ISPE (Pew/ISPE) launched a research collaboration to identify the multidimensional set of drivers behind shortages of sterile injectable drugs in the U.S. and to find out whether the decisions companies made to reduce risks of future shortages were influenced by correlations between drug shortages and elements other than quality-focused factors. The collaboration included the exploration of elements related to market uncertainties and product margins; supply chain network design; demand forecasting; and relationships between manufacturers and key stakeholders, including purchasing organizations and regulators. The results are presented in this report.

The study examined the following factors:

- Market forces. Aspects such as demand fluctuations, market uncertainties, the introduction of replacement products, and margins that inform a company’s ability to make investments in systems and facilities that can add more and/or redundant manufacturing capacity to address shortages.

- Business continuity planning. Decisions and plans that drive the ways companies design and structure their manufacturing networks to reduce the risk of supply interruptions by identifying backup manufacturing facilities, building new manufacturing lines within existing facilities, and/or establishing dual-source suppliers to react quickly to sudden, unexpected spikes in demand.

- Supply chain management. Capability of a company’s inventory management, demand planning, and forecasting accuracy to enhance the organization’s ability to proactively avoid a supply interruption by aligning the predicted demand volumes with the material inventory levels needed.

This study was designed to identify insights into the contributing factors behind shortages and the suggested areas for further exploration. The study was not designed to produce a statistically significant sample, given that the main objective was to understand key trends and identify the directional focus for future research.

More than 50 executives from 10 companies that collectively manufacture a mix of branded, branded-generic, and generic products participated in the research. The findings result from discussions with those executives, driven by a set of questions developed by Pew and ISPE, and also from 29 drug shortage examples, cited in the report as “reference products,” that the participating companies provided during the discussions.

The terms “companies” and “participating companies” are used interchangeably throughout this report. Similarly, “shortages” and “drug shortages” are used interchangeably.

Refer to the appendices for details on the research methodology, participating companies and executives, interview questions, and reference products.*

Summary of findings

Study results indicated that quality-related compliance issues are not the only factors driving the high number of shortages. The following are also key elements identified by these 10 companies:

- Market withdrawals. Market withdrawals, which reduced the number of manufacturers supplying a drug to the market, played a role in causing shortages. Companies highlighted a number of reasons that may have encouraged one or more manufacturers to exit a market, and therefore reduce the number supplying a drug to that market: quality issues, the introduction of replacement drugs into the market, and company decisions to realign a portfolio to focus on products with either greater margins or a higher risk of shortage. Refer to section 3.1 for details.

- Supply chain design. Companies identified the need to enhance their overall supply chains and in particular plan for and meet the estimated demand for a product by coordinating processes involving sales, demand planning, inventory management, and production. And even though companies said they had taken steps to build additional capacity—such as backup manufacturing or identification of dual-source suppliers—into their respective supply chains, not all products received the same level of manufacturing redundancies. Instead, companies established levels of redundancy based on manufacturing complexity, return on investment, and impact on patients if a shortage occurred. Refer to section 3.2 for details.

- Purchaser–manufacturer incentives. Companies said they needed incentives, either in the form of guaranteed-volume contracts or the ability to retain contracts, to mitigate the risks of making investments to prevent shortages. They said a lack of such incentives prevented them from entering a market to resolve a shortage issue or build the systems needed to prevent shortages. Refer to section 3.3 for details.

- Limited market insights into future demands. Without accurate information about the expected demand for a product, especially low-volume, low-margin products, companies felt reluctant to invest in setting up additional manufacturing capabilities to protect against future shortages. Participating companies commented on the need to improve both internal operations, such as sales and operations planning or demand forecasting, and the accuracy of external systems and programs they depended on for the market landscape information (such as how long a competitor would be out of the market). Refer to section 3.4 for details.

- Managing regulatory expectations. Companies said regulatory challenges contributed to shortages given the timescales and costs incurred in order to obtain approval to expand manufacturing capacity or upgrade a piece of equipment. They said the risks of a shortage increased when these regulatory challenges dissuaded them from making changes, especially to products developed 10 to 20 years ago, that might help meet an anticipated increase in demand. Refer to section 3.5 for details.

The study results indicate that, in addition to improvements in product and manufacturing quality and current Good Manufacturing Practice (cGMP) compliance, drug shortages could be reduced with improvements in internal-demand-forecasting abilities; overall supply chain maturity; and the relationships between a manufacturer, a provider, and regulators.

America’s Overdose Crisis

Sign up for our five-email course explaining the overdose crisis in America, the state of treatment access, and ways to improve care

Sign up

How Market Forces Contribute to Drug Shortages

Pew partners with pharmaceutical engineering organization to assess underlying issues